Flanges & Pipe Fittings – Cangzhou Hongmao

- Home

- Pages

- products

WN Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

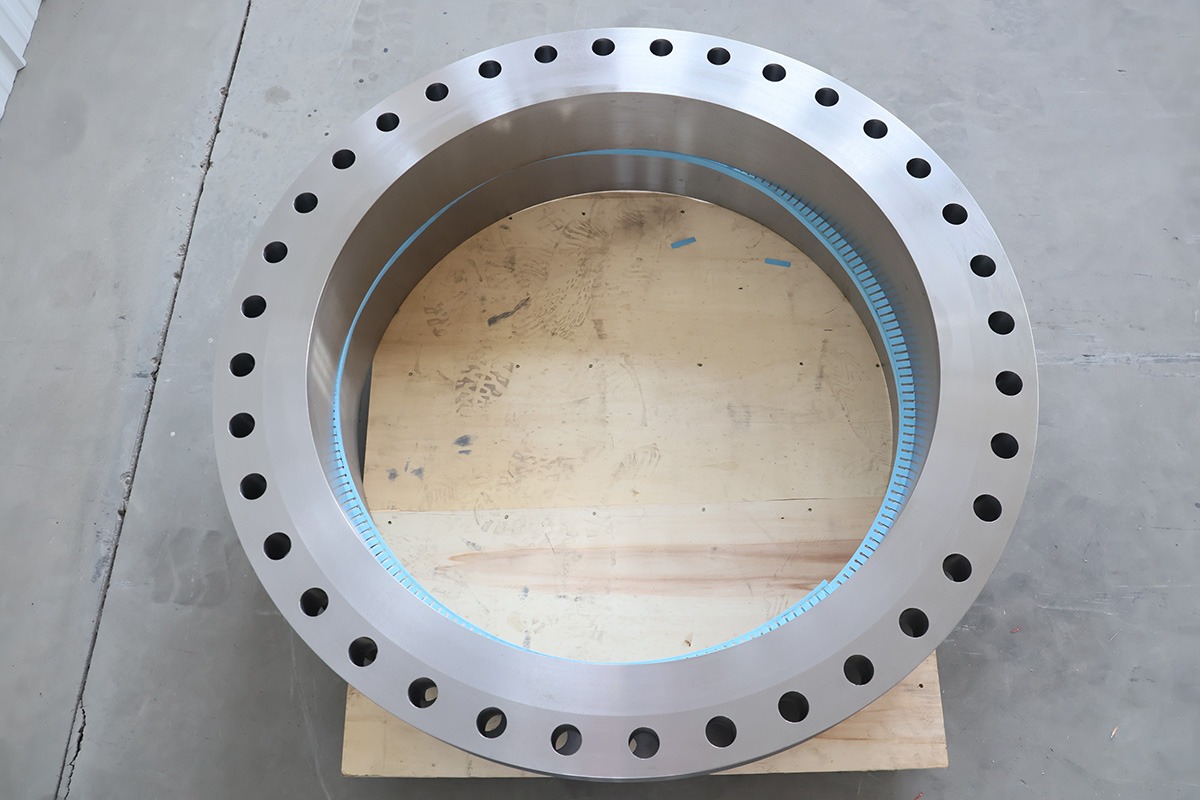

Spectacle Blind Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

SO Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

PL Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

BL Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

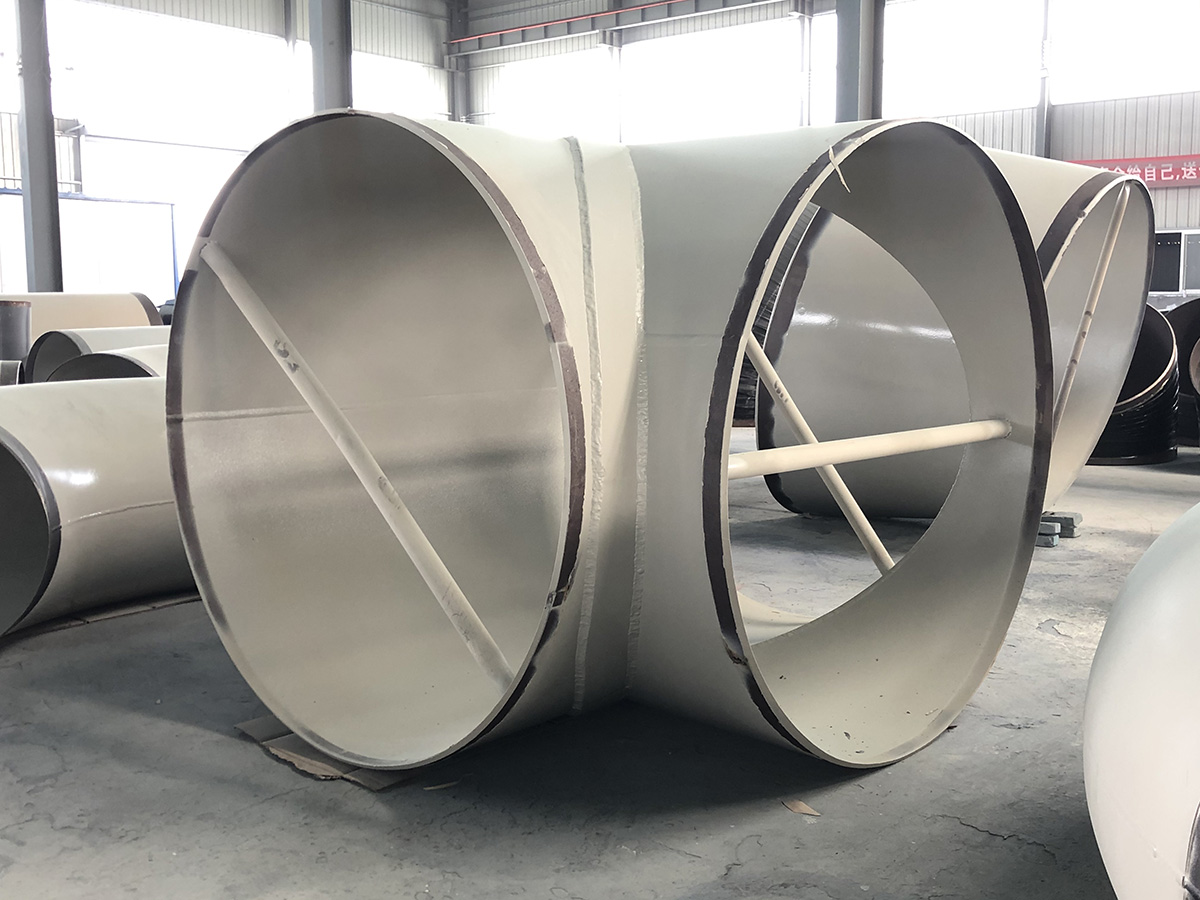

Equal Tee

- Product

- Equal Tee; Equal Cross

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Equal Cross

- Product

- Equal Tee; Equal Cross

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Eccentric Reducer

- Product

- Concentric Reducer;Eccentric Reducer

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Concentric Reducer

- Product

- Concentric Reducer;Eccentric Reducer

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Cap

- Product

- Cap

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

90° Elbow

- Product

- Stainless steel 45° Elbow ;Stainless steel 90° Elbow ;90° Elbow; 45° Elbow; 180° Elbow

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements