Quality Driven by Technology · Service Connecting the Globe

Cangzhou Hongmao Building Materials Co., Ltd. – Professional Manufacturer of Flanges and Pipe Fittings

Your Trusted Partner for Pipeline & Flange Solutions

"Based in China's Key Pipeline Equipment Manufacturing Hub, Delivering Reliable Industrial Connection Solutions Worldwide"

End-to-End Control

Certified Precision

Global Supply Expertise

Our Services

Cangzhou Hongmao Building Materials Co., Ltd. provides high-quality flanges, pipe fittings, and customized pipeline solutions for global customers. With stable quality, fast delivery, and professional technical support, we have become a trusted supplier for engineering projects worldwide.

Our manufacturing processes are eco-friendly, minimizing environmental impact through sustainable practices and innovations.

- Flange Manufacturing & Supply

- Pipe Fittings Production

- Custom Fabrication (Drawing or Sample Required)

- OEM & ODM Services

- Quality Control & Technical Support

- Export Support & Fast Delivery

WN Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

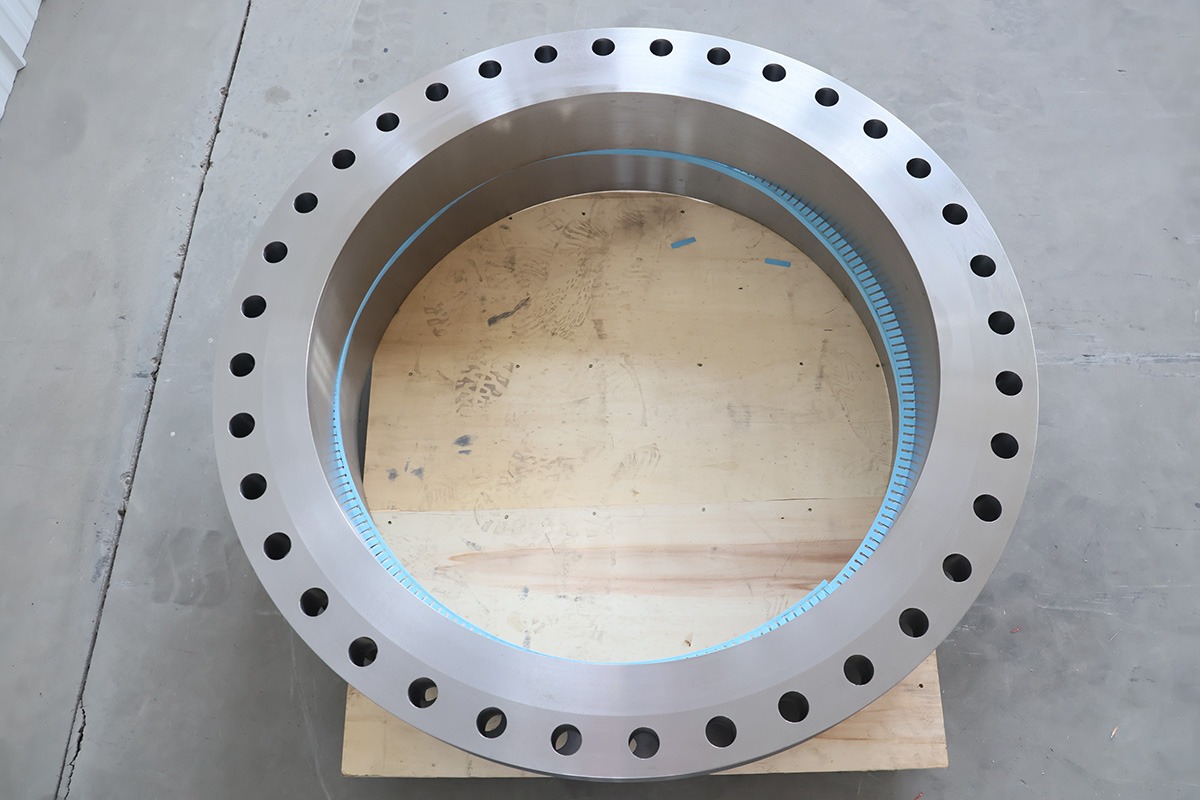

Spectacle Blind Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

SO Flange

- Technology

- Forging

- Size

- 1/2”-120”; DN15-DN3000

- Pressure Class

- 150#;300#;600#;900#;2000#;3000#;6000#;9000#

- Material

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5;WP9;WP11;WP22;NACE MR-0175;

- Standard

- ASTM A105N; A182Gr.F304/L; F316/L; A350LF2; A694F42 to F70;WP5; WP9;WP11;WP22;NACE MR-0175; Other Grade available on Request

- Coating

- Anti corrosive paint; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building;Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

1550+ Statified Users over The Globe

“Cangzhou Hongmao is our go-to supplier for critical flange projects. Their consistent quality and rigorous testing give us absolute confidence, which is priceless in the oil and gas industry.”

“We needed a batch of non-standard fittings for a tight deadline. Hongmao's team not only met our precise specifications but also delivered ahead of schedule. A truly reliable partner.”

“From initial inquiry to final delivery, the professionalism is outstanding. Their comprehensive service—custom fabrication, quality control, and export support—makes long-term collaboration effortless.”

Customer Satisfaction

On-Time Delivery & Quality Acceptance Rate

Employed With Us

Advance Factory

Worth Product Created

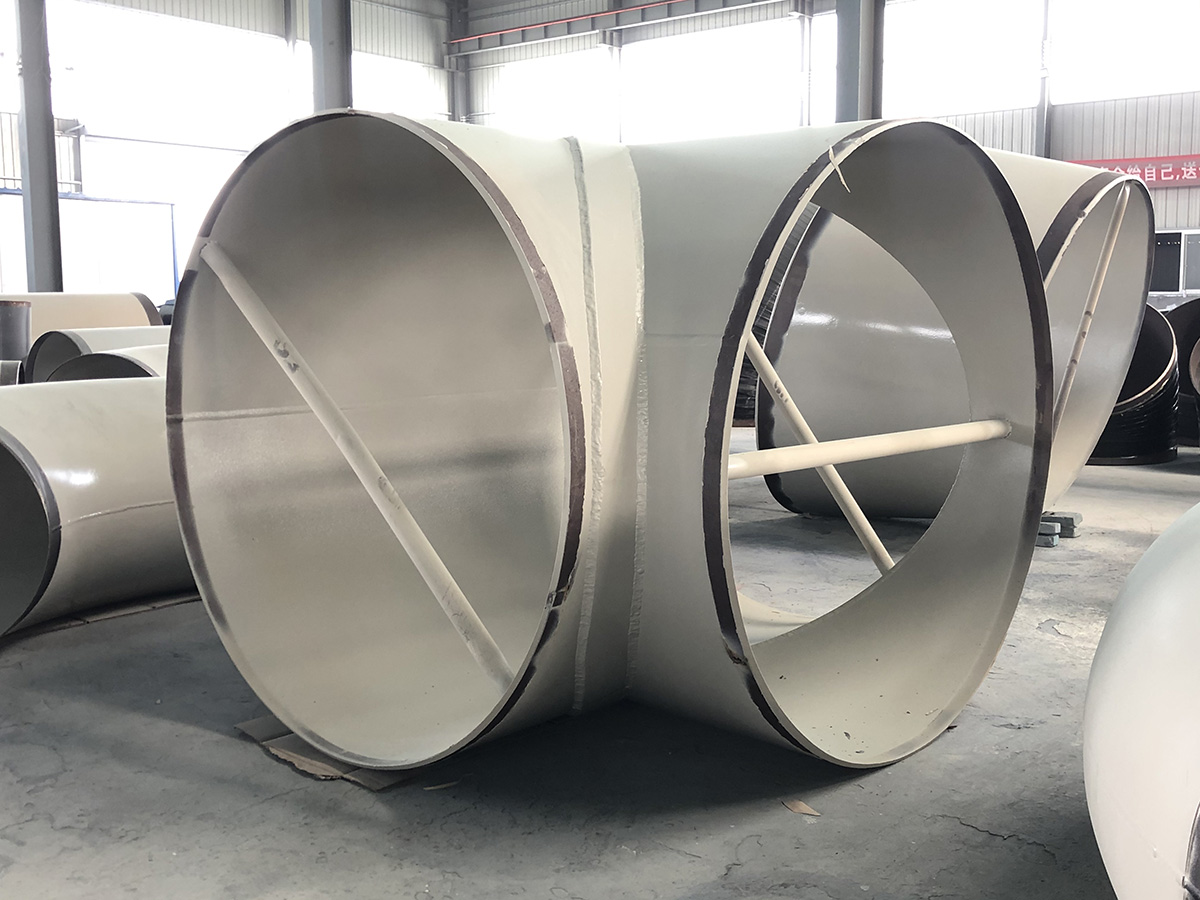

Equal Tee

- Product

- Equal Tee; Equal Cross

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Equal Cross

- Product

- Equal Tee; Equal Cross

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Eccentric Reducer

- Product

- Concentric Reducer;Eccentric Reducer

- Technology

- Seamless;Welded

- Size

- Seamless Size:DN15-DN1200 Welded Size:DN200-DN2000

- Thickness

- SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS;High Thickness To 150mm

- Radius

- 1D ;1.5D; 2D; 2.5D; 3D; 4D; 5D; 6D;10D

- Material

- A234-WPB;A420-WPL3/ WPL6;WP5;WP9;WP11;WP22;NACE MR-0175 API5L-X42/46/52/56/60/65/70/80(NS/MS) 403-WP304/L;WP316/L;S31803; 2205

- Standard

- ASME B16.9; GB12459; DIN2615; GOST17375; JIS B2311

- Coating

- Anti corrosive paint; 3LPE Coating; Galvanized (Hot Dipped Electro-Plating) etc.

- Inspection

- Chemical Elements; Mechanical Property; Metallographic Test,; HIC /SSC,; Heat Treatment,; Ultrasonic Test; Penetration Test; Magnetic Powder Test; X-Ray Test; Hydraulic Pressure Test; Blasting Experiment; we can make them according to your request.

- Application

- Water Disposal; Electric Power; Chemical Engineering; Ship Building; Nuclear Energy; Garbage Disposal; Natural Gas; Petroleum Oil.

- Note

- Our company can produce customized products according to customer requirements

Our news

news

Project & Applic…

CANGZHOU, China R…

Technology & Qua…

“Pipeline syst…

Showcasing Project S…

Cangzhou Hongmao Bui…

Latest News

Prime Recent Industrial News

Contact Us

Get in Touch for Quotes, Technical Support & Collaboration

How it Works?

- Fill Your Company Detail

- Select Services You Need

- Agreement and Contract